CNC prototyping or producing product samples with CNC technology is a process that necessitates the use of multiple types of CNC equipment. You can’t just hope to complete a CNC prototyping process just by using only one piece of equipment, such as CNC milling equipment. There will be other CNC machines you need to use as well, such as laser cutting, grinding, bending, waterjet cutting, robotic arms, and other CNC-related equipment.

Let’s take a closer look at the different CNC machines for prototyping and their advantages in your manufacturing production.

The Different CNC Machines for Prototyping and Their Advantages

- CNC Laser Cutting Equipment

Compared to the regular cutting tools you can use in CNC prototyping, the CNC laser cutting equipment uses a focused laser beam to cut through various types of materials. The use of a laser allows you to perform clean cuts of the material workpiece, which ensures that you can get the most accurate cuts for your prototypes.

Benefits:

- It offers a better cutter when compared to the plasma cutting equipment, with more accuracy and precision in each cut.

- You can use the laser cutting equipment to cut through both soft and hard materials for CNC prototyping.

- It supports cutting for highly complex designs, allowing you to have more flexibility in creating your prototype design blueprint.

- CNC Drilling Equipment

Just like the name suggests, the drilling equipment is the machine type used for various drilling operations, allowing you to create various types of holes around the material workpiece you are working on. Sometimes, you might need to place some holes in some intricate places around the workpiece, and this drilling equipment is capable of performing that operation for you. By using computerized programs, each hole can be drilled in the exact spot you need them to be.

Benefits:

- A wide range of configurations can be applied for each drilling operation. You can incorporate various parameters, such as feed and plunge rate, the depth of each drill, drilling speed, and many others.

- It supports a wide range of drilling operations, including drilling holes for places that are out of reach by the regular milling equipment.

- You can switch various drilling tools to accommodate complex design blueprint and make the whole prototyping operation faster to complete.

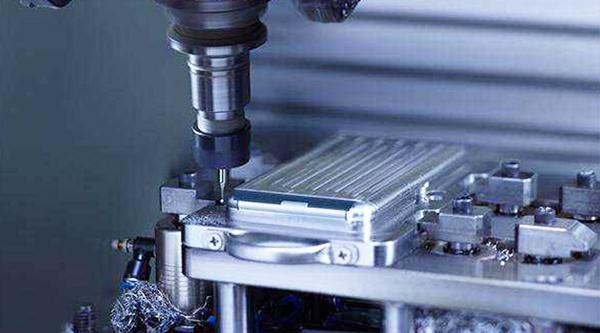

- CNC Milling Equipment

For the everyday machining activities, most manufacturers will use the CNC milling equipment, as it supports various operations, including cutting, milling, and drilling. With the milling equipment, you can use the G-code programs to guide its autonomous operations, following the design blueprint you have.

Benefits:

- Aside from milling, this equipment also supports drilling and cutting mechanisms, along with shoulder milling, face milling, turning, and tapping.

- It’s the best equipment you can use to work with hard CNC materials, such as those that are difficult to machine.

- You can configure it to work in up to 6-axis.

- CNC Lathe Equipment

The lathe equipment is used for producing prototypes with cylindrical shapes. You will need to insert the material workpiece into the rotating feeder of the CNC lathe equipment and then spin the workpiece while applying various cutting tools to it, until you get the prototype based on your design. The lathe equipment will restrict you to make products with only specific shapes, such as cylindrical, flat, and conical.

Benefits:

- Perfect for simple operations that require you to build cylindrical or conical prototypes.

- It has a more compact design compared to the milling equipment, and it is also more economical to use.

- It uses 2 axes that you can control by using computer programs, and you can also control various parameters of the lathe operations, such as the rotation speed and the cutting mechanisms you need to use.

- CNC Plasma Cutting Equipment

The plasma cutting equipment is another CNC cutting machine type you can use to cut various material workpieces based on your design requirements. However, the plasma cutting equipment uses the plasma gas to perform the cutting process, and you can only use it on material workpieces that are conducive to electricity.

Benefits:

- An accurate cutting method for metal workpiece materials, such as stainless steel, copper, and brass.

- You can also use this equipment to cut through hardened metals with high levels of hardness, such as titanium.

- It uses ionized gas charged with electricity until it reaches very high temperature, much higher than the material workpice’s melting point.

- CNC Grinding Equipment

The grinding equipment is the CNC machine type you can use to grind upon the surface of the material workpiece, often for the purpose of polishing the surface. So, after working with the material workpiece using the milling or lathe equipment, you will need to use the grinder equipment to smooth out any rough surfaces later.

Benefits:

- It can help increase the aesthetics of the prototype or product sample you are building.

- The CNC grinding equipment will be compatible with most abrasives sold in the market today.

- There are various types of CNC grinder, such as roll, cylindrical, and surface grinder equipment.

- CNC Bending Equipment

The bending equipment is the type of CNC machine you can use to press upon sheet metals and bend them according to your design requirements. There are various bending techniques you can apply on sheet metal materials using the CNC bending equipment, and each bend can be programmed to produce certain angles and accuracy based on your design.

Benefits:

- You can configure various bending operations and program the machine to work on these bending operations with the best accuracy and precision.

- This equipment can also work on bending pipes and rods with the same mechanisms as when you use it for bending sheet metal.

- It’s best for high-volume production, as the bending process is highly repeatable, with consistent accuracy and precision.

Conclusion

These are the common types of CNC machines you can use in your prototyping production, with each of their advantages. There are still many more types of CNC machines you can use, such as CNC router, waterjet cutting equipment, EDM or Electrical Discharge Machining, automation robots, and many others. Depending on your project, you might need to use multiple CNC equipment to get your prototyping project done.

TEAM Rapid is a CNC machining China service provider that provides the complete CNC prototyping services that are suitable for your project. Our factory in China uses multiple CNC-related machining equipment based on the project requirements.