There are many types of electronic cigarettes on the market, but for consumers, almost every electronic cigarette has a pain point, that is, oil leakage. On average, one-third of a bomb’s smoke is wasted in oil spills. What is an oil spill? That is, the smoke oil flows out in an abnormal way, such as leaking out from the outside of the glass of the atomizer, the base of the atomizer, the outside of the cigarette holder, etc.

Although there are a lot of solutions to the problem of electronic cigarette oil leakage, such as keeping the atomizer vertical, adjusting the air inlet, often cleaning the atomizer, etc., but these are only for consumer use to analyze, and can not solve the fundamental problem. Why the waterproof function of mobile phones, watches and other consumer electronic products is nearly perfect, and even resist the invasion of coffee, tea, soda and other liquids, why the oil leakage problem of electronic cigarettes has not been solved?

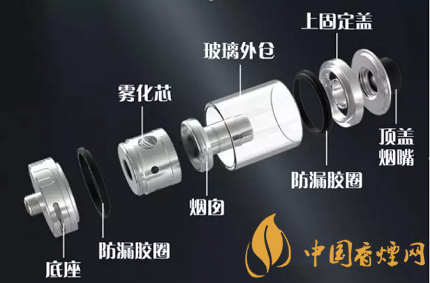

The following Xiaobian will simply analyze the problem of frequent oil leakage of electronic cigarettes. The oil leakage problem of electronic cigarettes will be analyzed from three aspects: structural parts, precision of accessories, and product design. In the recent release of several e-cigarettes have made improvements in oil leakage solutions, we look at these recent e-cigarette product solutions that focus on oil leakage. The popular small smoke flat smoke bomb structure in the market, the general structure is: sealing ring, atomization bin, guide rod, atomization core (fiber cotton/ceramic) and other accessories.

Perhaps the anti-oil design of electronic cigarettes can refer to the waterproof of mobile phones. Below, according to the main structure of the cigarette bomb, how to improve the electronic cigarettes on the market for oil leakage?

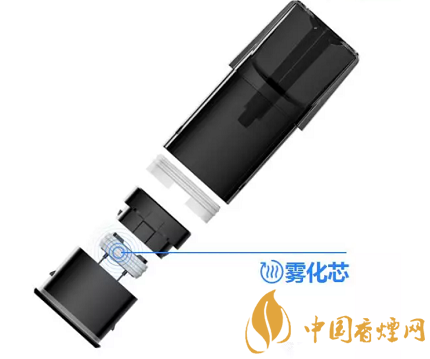

First, atomization core

In the face of the changing needs of smokers, under the premise of ensuring the degree of taste reduction, McWell launched the Feelm technology atomizer completely sealed components, which can prevent the leakage or dripping of electronic cigarette liquid. At present, Yuetke RELX and YOOZ adopt this Feelm ceramic atomization core technology for leak-proof design. Moreover, the ceramic material itself has strong oil affinity and is easy to conduct soot. Compared with cotton and other materials, ceramic will not have dry burning problems.

Second, atomizer structure design

Most of the popular oil storage structures in the market are directly assembled by atomizing silo, guide rod, base, atomizing core and other accessories, which requires high precision between product structures. This combined structural design is easy to lead to oil leakage up and down when the tightness is not high.

1. JVIC system

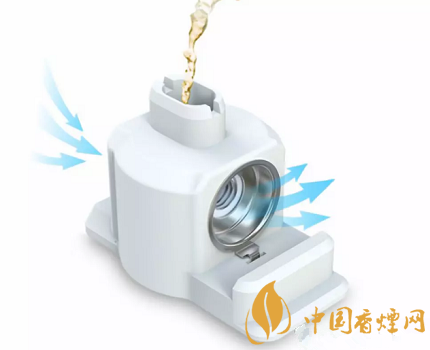

JVIC adopts the innovative and unique JVIC system (liquid vertical injection coil) to separate the intake, oil intake and oil output to effectively improve oil leakage.

2. Multiple protection

In addition to this JVIC system design, FLOW Fulu e-cigarette has been a hot topic recently, and it is understood that its waterproof level has reached IP56, “can prevent strong splashing water”. In response to the “oil leakage” phenomenon, FLOW Fluo has added a “four-fold protection” to the product, including a symmetrical oil absorption cotton on the top, a screw seal on the bottom, a mushroom type ceramic atomizer, and a symmetrical oil absorption cotton on the bottom.

3. Oil core separation structure

The BTX Small Apple recently launched by Baotianxiang Technology (factory) adopts a new type of leak-proof patent. The smoke bomb uses cotton core induction heating sheet and oil core separation technology to resist oil leakage! Enclosed smoke bomb, smoke bomb is the use of closed oil storage bin, atomization bin, condensate collection warehouse three structural design.

Three, sealing ring

For electronic consumer products with high sealing requirements, reinforced coatings and sealed designs are generally used. In addition to the atomization core and the overall structural design, there is also a sealing artifact – a sealing ring. The sealing ring is distributed in the most connecting ports of electronic cigarettes. Due to the high requirements of electronic cigarettes on materials, the material around the atomizer uses FDA food grade materials, and liquid silica gel benefits from its soft, non-toxic, high and low temperature resistance, easy molding and other characteristics, through LSR injection or secondary injection molding, widely used in 3C electronics such as mobile phones, phone watches and other shells, Cato or interface positions, play an important role in sealing and waterproof. At the same time, the sealing ring of the electronic cigarette seal design also plays an extremely important role.

The nebulizer is combined with the battery rod, and most products are connected by sealing rubber rings and threads. The silicone ring is almost distributed in each connection part of the nebulizer base, and the e-cigarette thermal conductive silicone and thermal conductive silicone sheet are necessary accessories to prevent oil leakage and improve sealing.