Undoubtedly one of the most talked-about models in the 3D printing community recently, the unveiling of the Anycubic Kobra 3 Combo has sparked significant interest. As another entrant into the competitive market of multi-color 3D printing, this new model from Anycubic stands alongside other notable entries like Bambu Lab and Creality. This move signifies a growing trend among Chinese 3D printer brands to innovate in the realm of multi-color and high-speed printing. With a starting price of $449 under an early bird offer, the Kobra 3 Combo offers a compelling package for enthusiasts and professionals alike. This review delves into its design, features, and overall performance to assess its value proposition.

Design

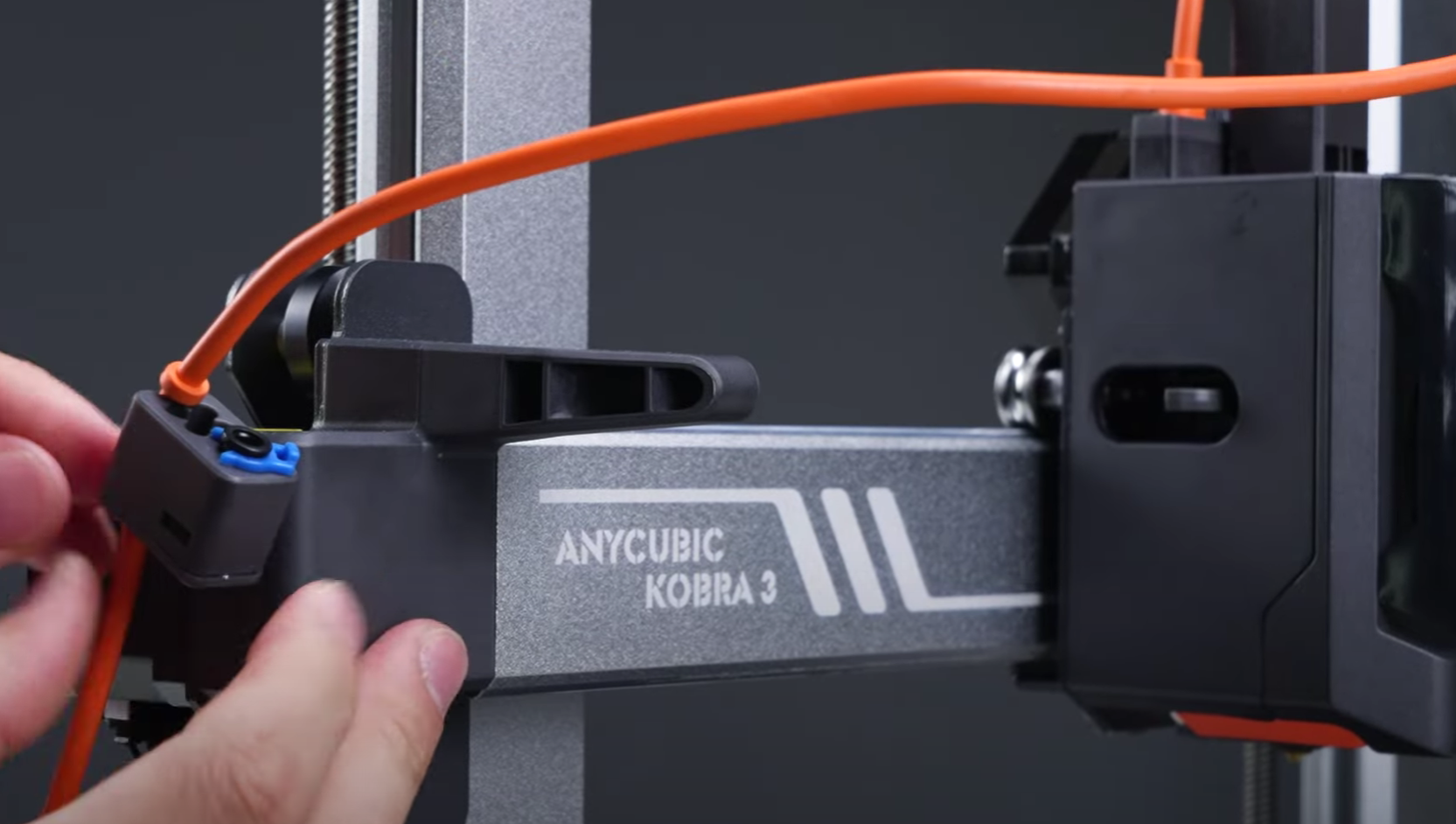

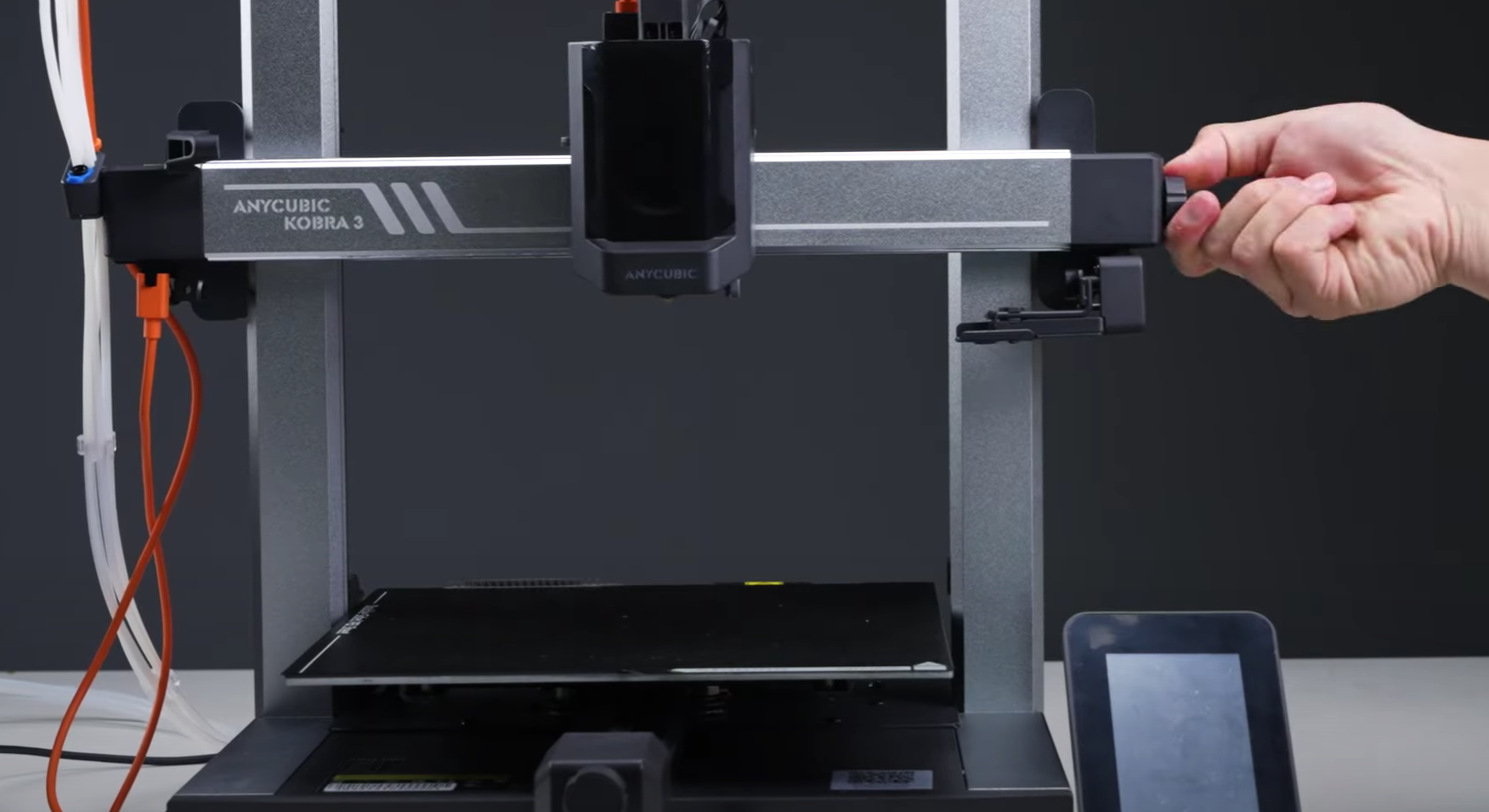

The Anycubic Kobra 3 Combo showcases a sleek and functional design that caters to both aesthetic and practical needs. The printer features an open bed design, which is becoming increasingly popular due to its accessibility and ease of use. The machine dimensions, measuring 452.9 x 504.7 x 483 mm for the printer and 365.94 x 282.84 x 234.5 mm for the ACE Pro, make it a compact yet robust addition to any workspace. The inclusion of a PEI spring steel build platform adds to the durability and ease of print removal, making maintenance straightforward. The front panel is equipped with a port for connecting the Anycubic Color Engine (ACE), facilitating easy transitions between colors and enhancing the overall user experience.

Features

Anycubic Color Engine (ACE)

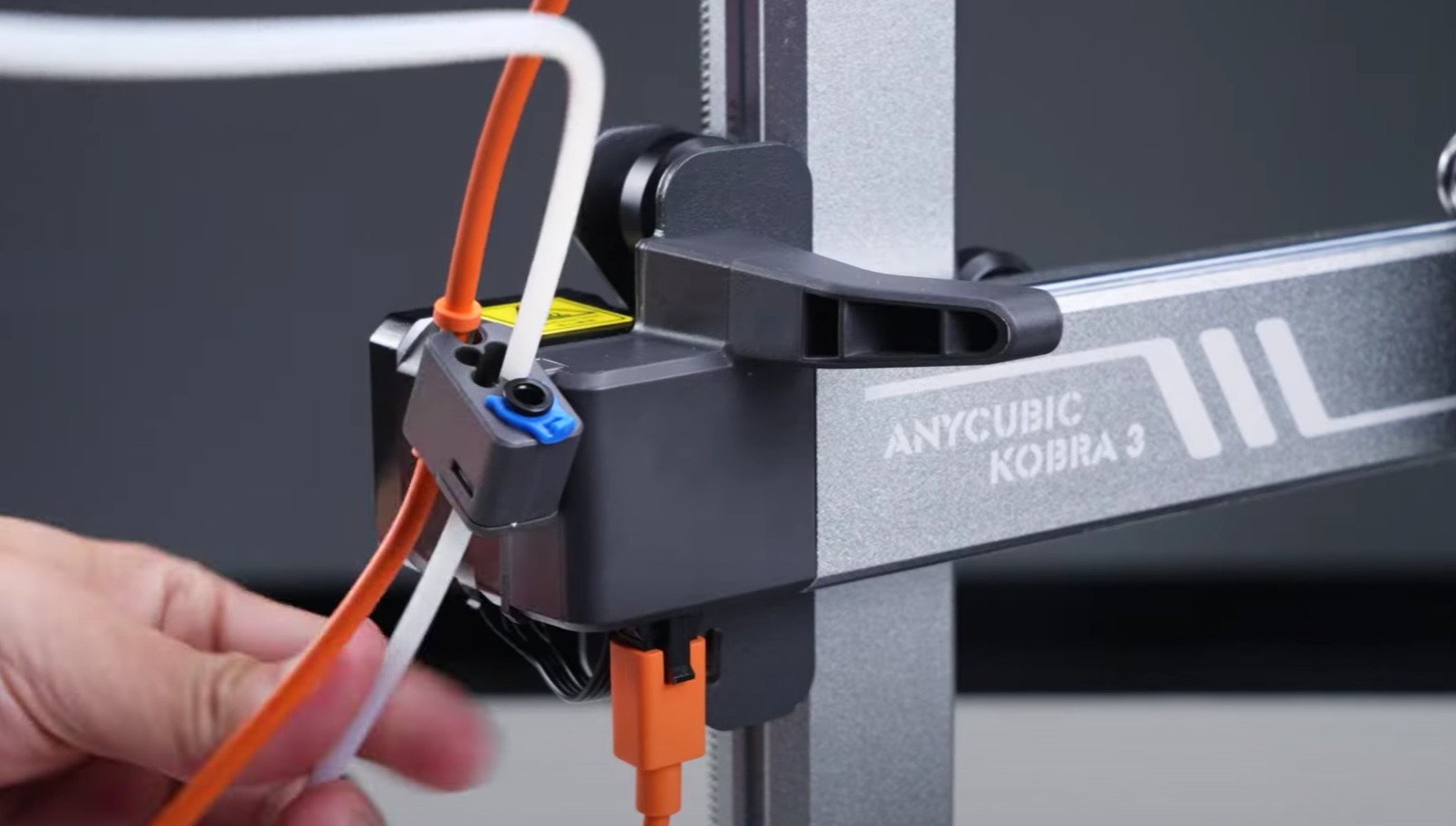

One of the standout features of the Kobra 3 Combo is its Anycubic Color Engine (ACE), a sophisticated multicolor print system. The ACE allows for seamless integration of up to four filaments, with potential expansion to eight colors if a hub is introduced in the future. This system is designed to minimize filament change downtime, as it only retracts the filament a short distance for swift swaps. The ease of loading filaments into the slots, which accommodate both plastic and cardboard spools, is a notable improvement in user-friendliness.

Drying While Printing

The filament storage box and multimaterial unit serve a dual purpose as a dry box. Controlled through the 4.3-inch touchscreen interface, users can schedule drying cycles according to the filament type, even while printing. This feature eliminates the need for separate drying equipment, streamlining the process and ensuring optimal filament condition. The box does require a separate power supply, but this is a minor inconvenience compared to the benefits it offers.

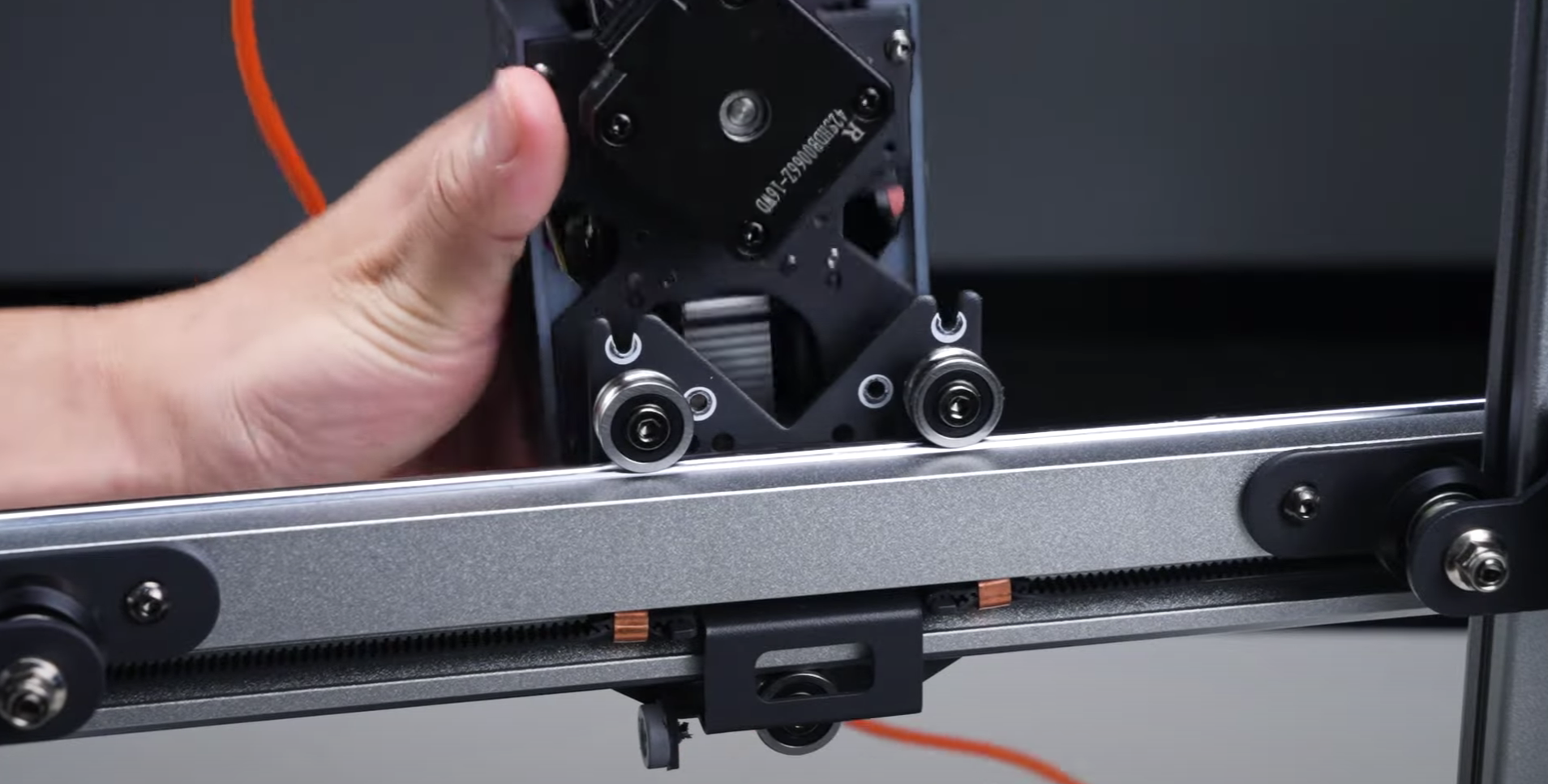

Extruder

The Kobra 3 extruder is capable of reaching temperatures up to 300°C, enabling the printing of a variety of challenging materials, including PETG, ABS, ASA, and some nylons. However, the open-frame design might limit the efficiency of printing certain materials like nylon. The extruder is equipped with a toolless nozzle change feature, simplifying maintenance and reducing downtime. The cutting mechanism further enhances convenience by making nozzle changes swift and hassle-free.

Specifications

The Kobra 3 Combo boasts a build volume of 250 x 250 x 260 mm and a maximum printing speed of 600 mm/s. The power supply is rated at 400W, and connectivity options include USB flash drive, Wi-Fi, and AC Cloud. The build platform uses a PEI spring steel sheet, which is magnetically attached for easy removal and cleaning. The printer supports various materials, including PLA, PETG, ABS, ASA, PET, PA, PC, PP, and HIPS. The automatic leveling system, vibration suppression, flow control, and Z-axis free compensation contribute to a high level of precision and ease of use.

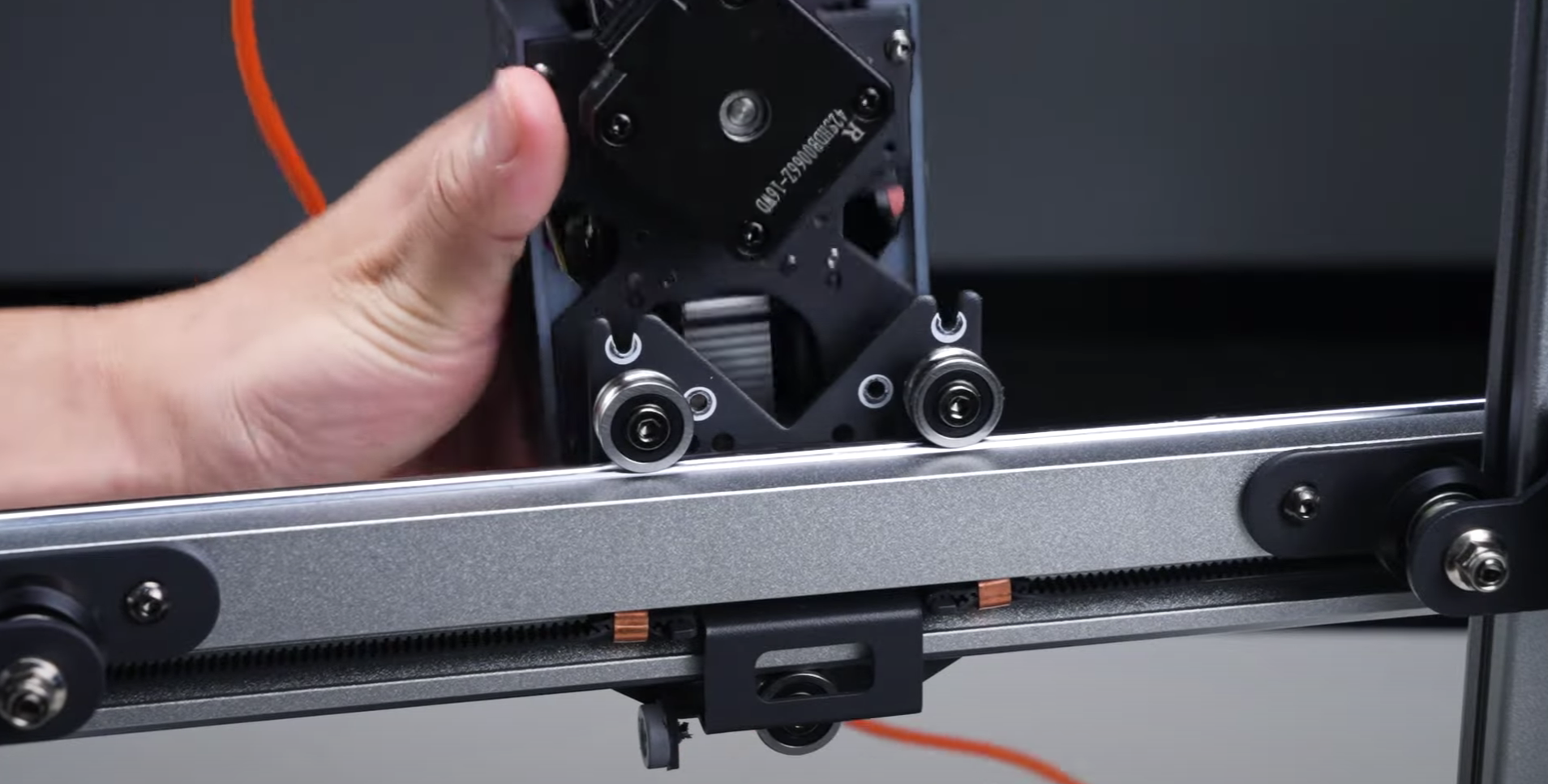

Print Volume

The Anycubic Kobra 3’s bedslinger-style design provides a generous build volume of 250x250x260mm, allowing for the creation of sizable prints. The flexible PEI sheet on the print bed ensures that removing completed prints is effortless, simply by flexing the sheet. Maintaining a clean print bed is crucial for optimal adhesion, and the Kobra 3 makes this easy with its re-leveling capabilities before each new print.

Print Speed

With a printing speed exceeding 600 mm/second, the Kobra 3 Combo stands out in its class, competing with high-speed printers like the Creality K1C and Bambu Lab’s models. This rapid printing capability is particularly advantageous for users who need to produce parts efficiently and quickly.

Slicer Software

Anycubic has introduced a new slicing software specifically for the Kobra 3 Combo. This software allows for painting directly on the object, enhancing customization options. Additionally, users can opt for the popular Cura slicer, or for those who enjoy deeper tinkering, the Orca Slicer, which is similar to Bambu Slicer, is also compatible. This flexibility ensures that users can choose the software that best fits their workflow and preferences.

Verdict

The Anycubic Kobra 3 Combo is a significant contender in the 3D printing market, particularly in the multi-color printing segment. With its competitive pricing, especially during the early bird offer, and a rich feature set that includes the ACE multicolor system, drying capabilities, high-temperature extruder, and a user-friendly design, it offers substantial value. The ability to handle a wide range of materials, coupled with high-speed printing, positions it well against rivals like the Bambu Lab A1 Combo. While there are minor inconveniences, such as the need for a separate power supply for the drying box, these are overshadowed by the printer’s overall capabilities and performance. For both enthusiasts and professionals seeking a reliable and versatile 3D printer, the Anycubic Kobra 3 Combo is a worthy investment.

Watch Anycubic Kobra 3 Combo 3d printer unboxing and guide:

Read Also: Anycubic Photon Mono M7 Pro 3D Printer Review: Auto-Adaptive Technology